Turnaround management

Turnarounds are major events, often due to their size, length of preparation, the costs, investments, and loss of production involved, and mandatory inspections. They are also called ‘revisies’ (energy), ‘Stilstände’ (Germany), or shutdowns (chemicals). Turnarounds aim at long-term maintenance, improvements, and upgrades. They’re a balancing act between production demand, high-quality asset management, safety (SHE), and reliable performance. Achieving this balance demands expertise and a tailored approach to meet your unique challenges.

How turnaround time impacts your operations

Turnaround management requires balancing preparation and execution time. The turnaround time has a direct impact on plant performance, operational efficiency, and overall costs. Managing this time effectively reduces downtime and ensures smoother production schedules. Achieve seamless turnaround execution and maximize your efficiency with PDM’s proven STOPflow approach.

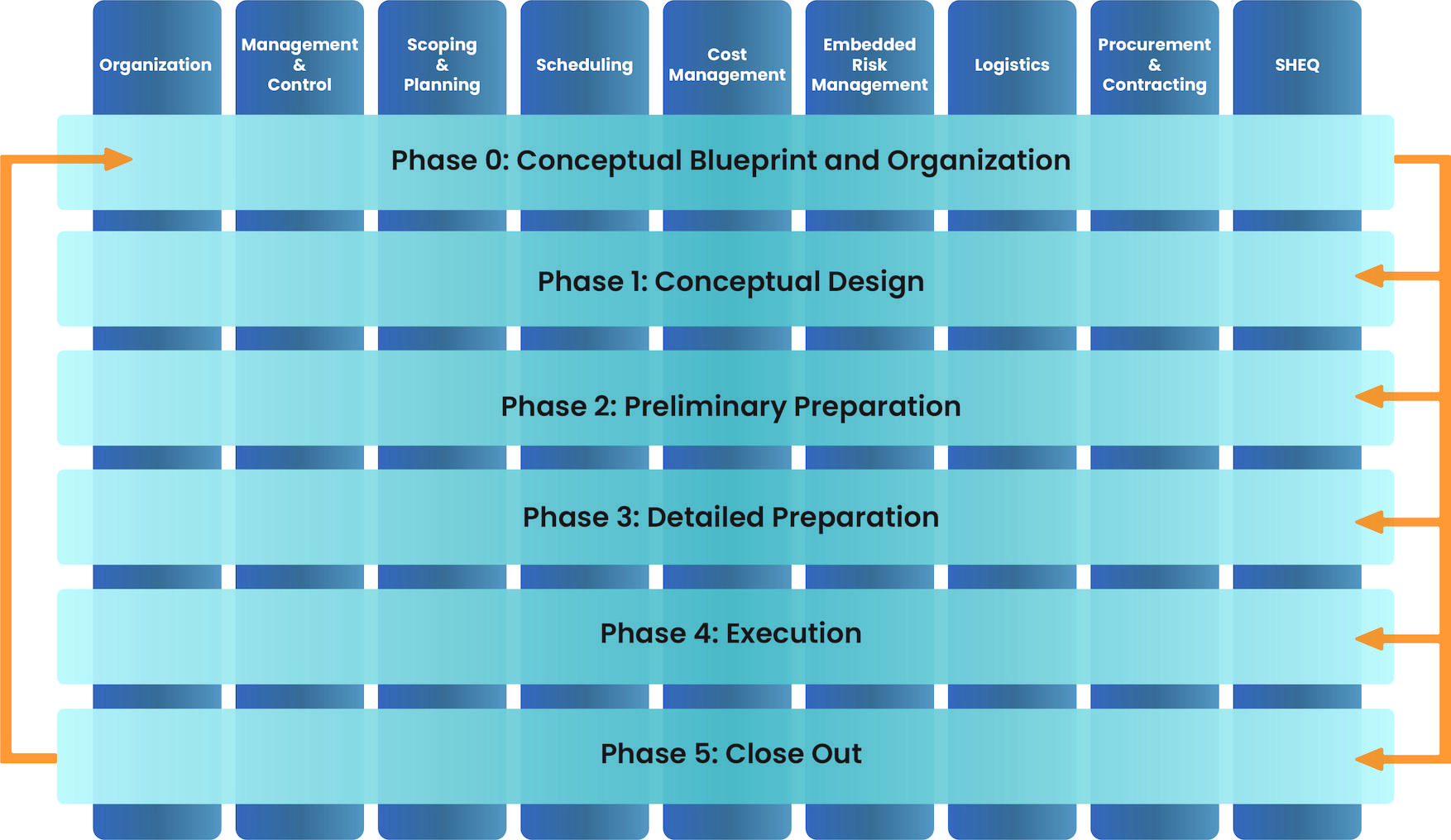

STOPflow model

The challenges of turnaround management

Challenges to be met and to navigate through are considerable:

- The risk of the domino effect during the execution and the limitations of learning curves due to the duration of intervals.

- The dynamics of lengthy preparations versus fast-track execution, extending or reducing intervals, and managing the chain of interdependent plants.

- Scope definition and freeze, planning, scheduling, and cost management.

- Availability of resources and contractors, contractor management, and balancing downtime versus availability.

- Balancing the focus between the turnaround itself and the long-term objectives: SHEQ, reliability, asset management, and the impact on plant performance.

turnaround strategy and execution

The management of a turnaround requires a specific form of project management while also being part of long-term program management. This includes:

- Strategic considerations and plant performance optimization.

- SHEQ and asset management development.

- Aligning execution with broader turnaround management goals.

Discover how our services contribute to sustainable improvements and effective execution.

Our turnaround STOPflow model

The STOPflow model was developed by PDM and has become an industry standard for preparing and managing turnarounds. Over the years, PDM has participated in and managed around 250 turnarounds, ensuring measurable improvements and alignment with strategic goals.

This structured approach provides the foundation for effective preparation and execution, helping companies minimize downtime and optimize performance. Discover more about PDM’s way of work and how we support the STOPflow approach.

Today, our ability in turnarounds focuses on the challenges to be met, the navigation to be managed, and empowering project management. Our experts excel at:

- Improving project efficiency.

- Innovating execution strategies.

- Connecting turnaround efforts to long-term objectives.

Turnarounds run more smoothly when the overall organizational process is streamlined. Discover how organizational development strategies provide the foundation for effective turnaround management, ensuring both project success and long-term organizational growth.

PDM’s turnaround services & methodology

Effective turnaround management is about more than just execution; it’s about aligning strategy, expertise, and innovation to deliver measurable results.

With PDM’s proven STOPflow model and expert guidance, your organization can achieve operational excellence while securing long-term reliability. Curious how we can optimize your next turnaround for success?