Design & Engineering

The Eindhoven region, stretching from Leuven in Belgium to Germany, is Europe’s most innovative technology hub. Here, over 5,000 high-tech and IT companies collaborate, driving advancements in design engineering and process optimization. Across the Benelux and Nordrhein-Westfalen, manufacturers like you are in constant pursuit of technological innovation to stay competitive.

The need for technological innovation

High-tech companies thrive on strong partnerships and co-development to fuel continued growth in design engineering. Collaborations with OEMs, ODMs, and technology designers are essential. However, transforming production processes independently can be challenging, revealing the need for effective engineering management and technical consulting services to help you achieve your goals.

Key challenges in design engineering

Your drive to innovate in design engineering is likely motivated by changing customer demands, fierce competition, and the pursuit of technological leadership. Here are some of the core challenges you may face:

- Scaling up operations and improving process cycle efficiency.

- Reducing costs while enhancing product quality.

- Navigating labor market constraints and skills shortages.

- Staying focused on your core business activities without getting bogged down in complex processes.

Unlock opportunities with co-development and outsourcing

By embracing co-development and outsourcing, you can effectively address these challenges. Here’s how your company can benefit:

- Assessment and redesign: conduct pain/gain analysis, conceptual redesign, and build a solid business case for existing production equipment.

- Cost of Goods (CoG) optimization: reduce costs and enhance the quality of subsystems.

- Quality improvements: optimize design and material use to minimize delays during prototyping and production.

- Advanced technological expertise: access essential support with technical engineering support, including design-to-function strategies, roadmaps, and business case development.

- Preventive maintenance and lifecycle management: extend the operational life of your machines with planned maintenance and effective product lifecycle management.

- Scaling up production: increase capacity, refine specifications, and accelerate throughput to meet market demands.

- Time to Market acceleration: speed up your development process through co-development and access to enhanced resources and expertise.

- Outsourcing responsibility: transition from input-driven services to responsibility-driven solutions for improved cost performance.

- High-value design solutions: compete effectively with superior project management, best practices, and industrial engineering services.

- Cradle-to-Cradle lifecycle management: implement end-to-end solutions from concept to end-of-life management.

- Industrialization and feasibility studies: focus on designs that maximize manufacturability, reliability, and cost efficiency, supported by feasibility studies and proven concepts.

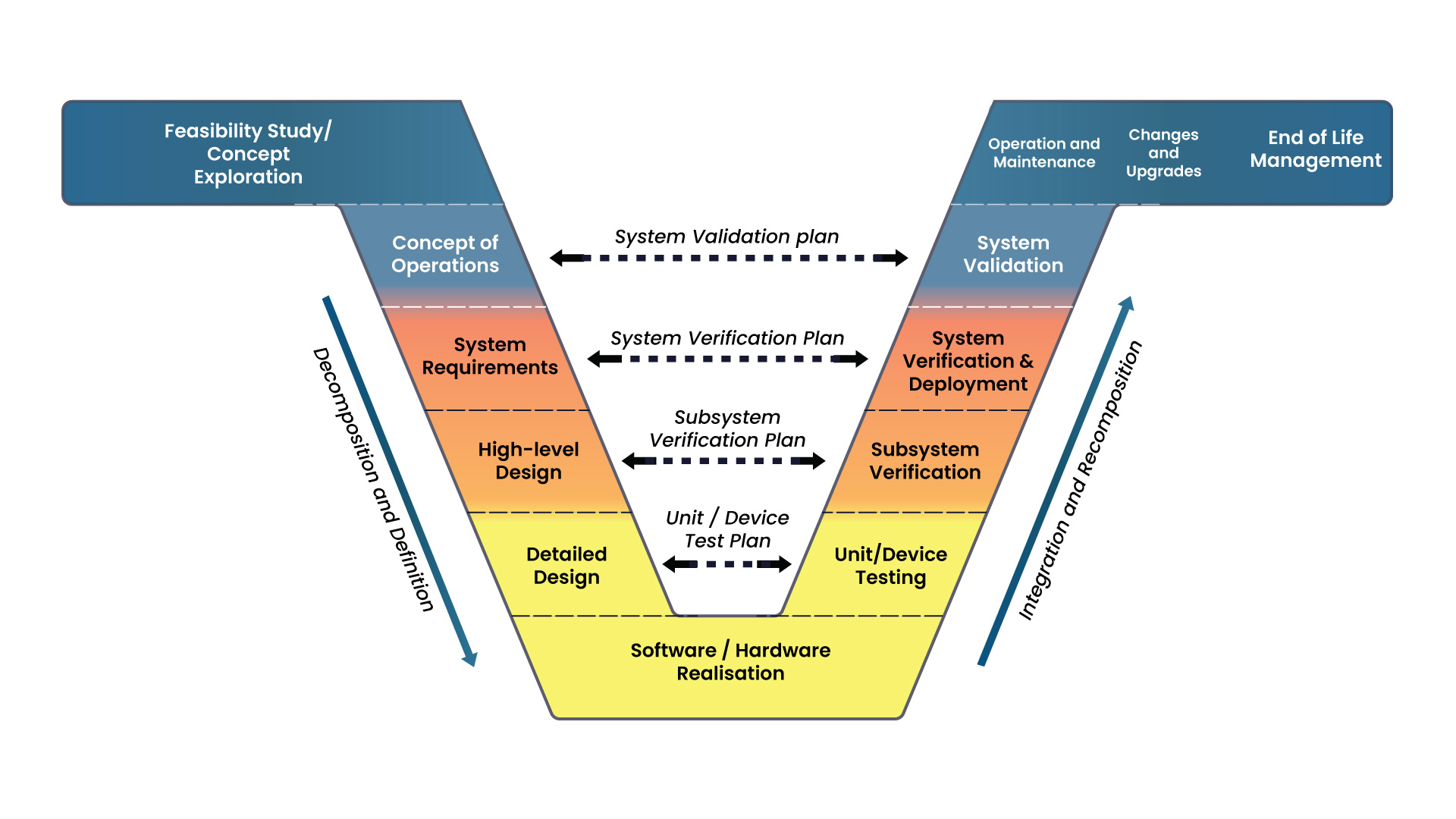

Your specific needs require a strategic approach that evolves alongside your project. At PDM, we use the Derisk Model to balance risk and technical readiness throughout the design engineering process. This model ensures that risks are systematically reduced as readiness increases, giving your project the foundation it needs for success.

The Derisk Model begins by addressing high-risk areas early in the timeline, leveraging strategic analysis and expert support to minimize uncertainties. As technical readiness grows, the focus shifts toward refinement and validation, with a smooth transition to the trusted V-Model for implementation. This approach allows us to guide your project through its entire lifecycle with precision and confidence.

By combining proactive risk management with scalable technical solutions, PDM helps you accelerate innovation while maintaining control over quality, costs, and timelines.

Taking responsibility for project management

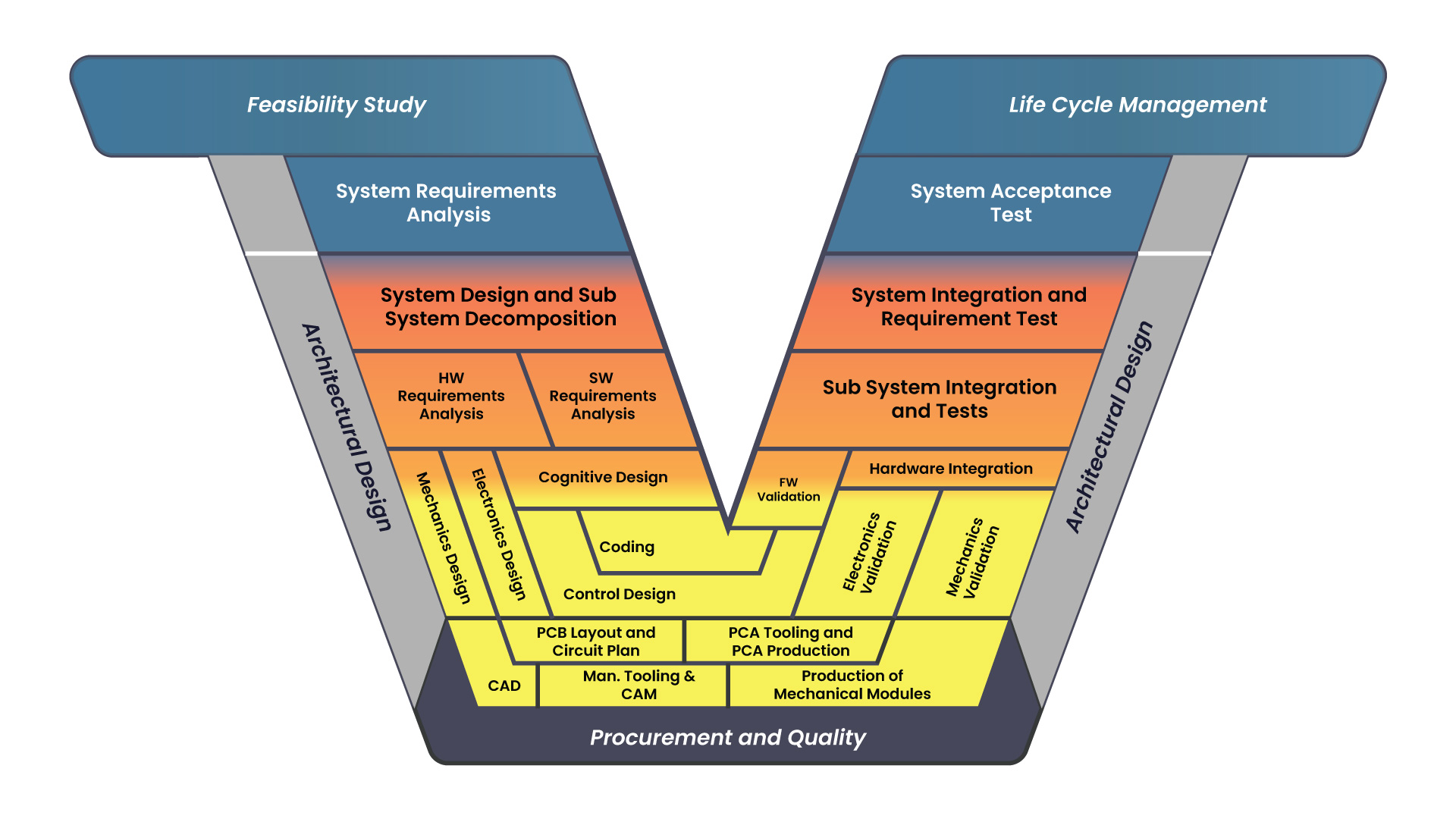

Effective project management in design engineering is one of our core strengths. We take responsibility across every stage of your project, from prototyping to manufacturing, following the trusted V-model for system design to ensure successful results.

The V-Model approach

We use the V-Model methodology, integrating our expertise at each stage of your design process:

- System requirements analysis: identify your system needs and break them down into hardware and software requirements.

- Mechanical and electronic design: develop detailed CAD drawings, PCB layouts, circuit plans, and software control designs tailored to your project.

- Production and assembly: manufacture mechanical, electrical, and electronic parts, followed by rigorous validation at the subsystem level.

- Integration and testing: finalize the process with hardware integration, subsystem testing, and acceptance testing.

- Lifecycle considerations: manage cost, quality, and lifecycle from start to finish, even after your product has been deployed.

For a deeper understanding of our approach, explore our expertise in production, asset management, and maintenance. These areas provide comprehensive support throughout your asset lifecycle, ensuring that every stage of your project benefits from industry-leading practices.

Continuous support and optimization

Even after your product is deployed, we remain by your side, providing support, updates, and enhancements as needed. Our commitment to organizational development and process optimization ensures that every solution we deliver stays efficient, reliable, and aligned with your business goals.