Maintenance management

Value-driven maintenance strategy

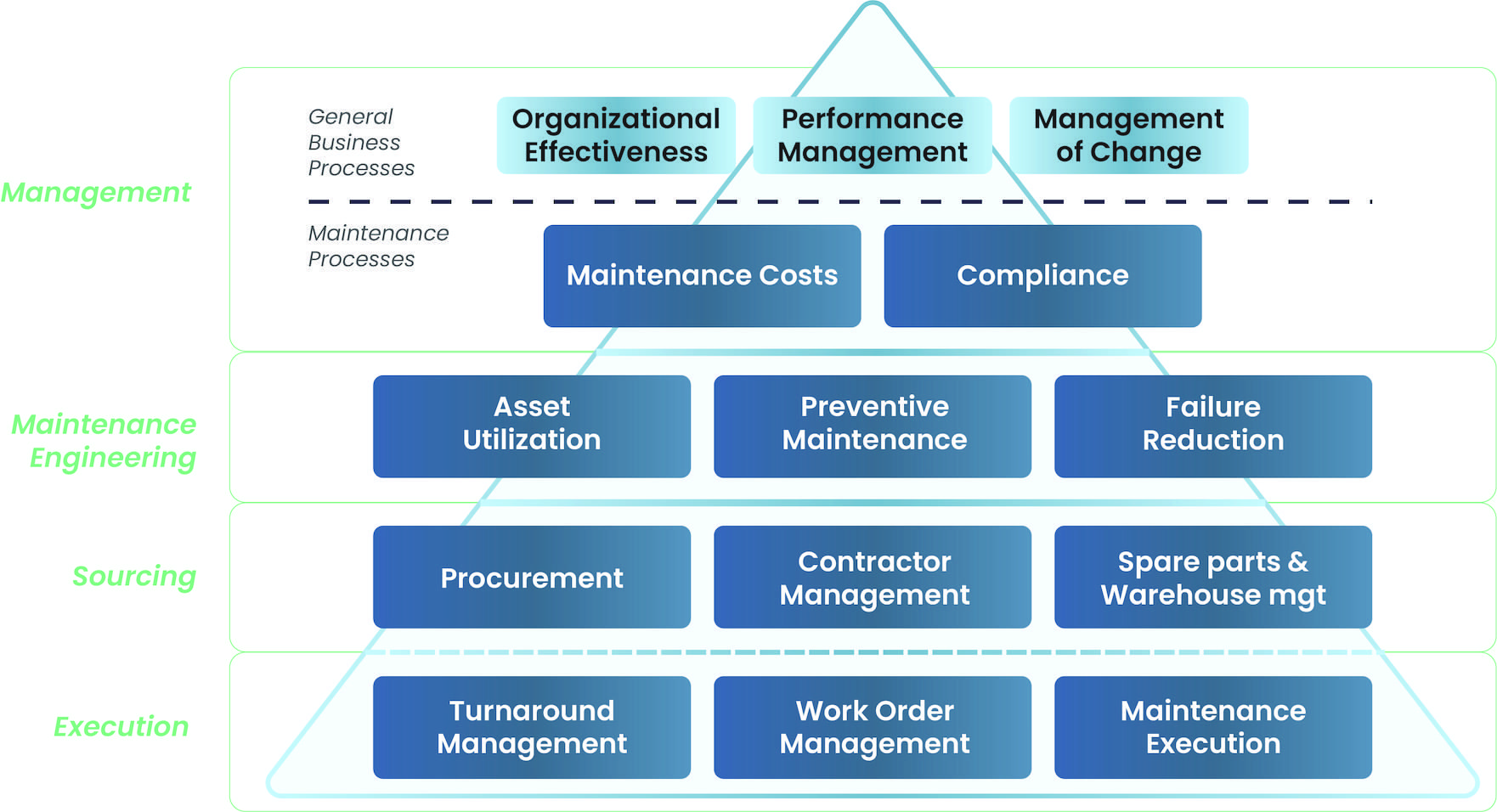

At its worst, maintenance is viewed as a cost center—subservient to production and far from a true partner in asset management. Yet, with the right maintenance strategy, many production companies could unlock significant potential, turning maintenance into a value generator. Discover how PDM can help you develop a maintenance strategy that drives value and ensures sustainable success.

Elevating maintenance strategy for lasting impact

In traditional settings, production often maximizes availability, pushing maintenance into a reactive, firefighting role. This reactive approach frequently makes maintenance the first target for cost reductions. Over time, plants age, availability decreases, and the overall equipment effectiveness (OEE) becomes reliant on the expertise of operators and technicians. When even they can no longer bridge the gaps, the system reaches a breaking point.

Management is aware of the risks, but often lacks a roadmap for effective change. By leveraging PDM’s organizational development expertise, companies can create a clear and actionable plan to break this cycle and drive lasting improvement.

A challenging situation—but not an insurmountable one. Companies can escape this cycle by adopting a forward-thinking maintenance strategy.

Challenges in developing a maintenance strategy

Developing a successful maintenance strategy requires overcoming common challenges such as misalignment, outdated processes, and resistance to change. These steps provide a clear path to tackle these issues effectively.

- Develop a vision for asset management.

Develop a vision, mission, and program that positions maintenance as a cornerstone of effective asset management. Ensure alignment across all stakeholders, including production, engineering, and maintenance teams. Curious how? Learn how PDM’s asset management expertise can help you achieve this.

- Build a strong business case.

Assess the current state and define the desired future. Highlight cultural, operational, and maturity considerations, supported by a change-management program. - Establish reliable processes and systems. Develop management systems, roles, and responsibilities to support a predictive and proactive approach to maintenance.

Benefits of an optimized maintenance strategy

An optimized maintenance strategy transforms operations by boosting reliability, reducing downtime, and aligning with industry standards. By adopting predictive tools and training teams effectively, companies can move beyond reactive approaches and secure long-term success. The following maintenance practices with best-in-class standards, unlocks hidden value in your operations:

- Leverage predictive maintenance tools.

Define maturity-related KPIs to track progress. Implement predictive maintenance tools, software, and technologies to enhance reliability and reduce downtime.

- Ensure compliance with industry standards.

Align maintenance practices with standards such as ISO and ESG to ensure compliance and sustainability. Discover more about how PDM supports effective turnarounds.

- Invest in training and competence development.

Equip teams with the skills and methodologies needed to adopt a reliability-focused mindset. Facilitate training in predictive maintenance solutions and related technologies.

How to implement predictive maintenance

Implementing predictive maintenance may seem complex, but it’s achievable with the right tools and mindset. From leveraging advanced software to integrating a reliability-centered approach, this process ensures assets are monitored and maintained efficiently. Let us guide you step-by-step toward a maintenance system that minimizes risks and maximizes performance.

- Adopt advanced EAM software.

Implement an enterprise asset management system (EAM) to streamline processes, manage spare parts, and support risk-based maintenance. - Integrate a reliability-centered maintenance (RCM) approach. Use an RCM tree structure to collect and organize essential data, laying the groundwork for preventive and predictive maintenance. See how PDM’s design & engineering expertise can help.

Partnering with PDM for maintenance optimization

For over 50 years, PDM has partnered with production companies to elevate maintenance from reactive to proactive. We combine deep expertise in predictive maintenance systems with practical change management to help leadership teams craft strategies that deliver results.

With the right maintenance strategy, your organization can transition from firefighting to forward-thinking, unlocking a culture of reliability, innovation, and operational excellence. Discover how PDM optimizes your maintenance for lasting impact.